Automated Packaging Opens New Competitive Advantage for Businesses

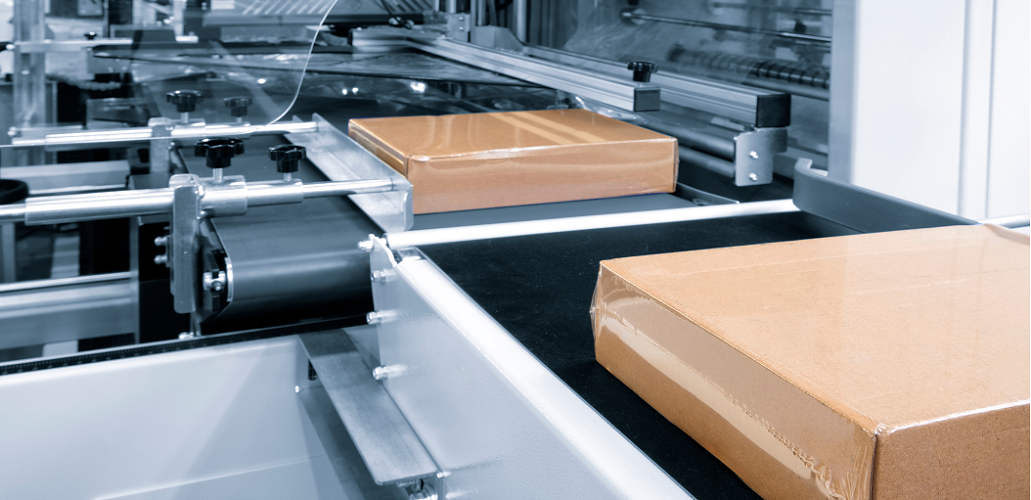

Automation packaging is using automatic or semi-automatic machinery at various stages of the packaging process, such as automated boxing, sealing, filling, wrapping, labeling and other functions, almost all industries can benefit from it. It aims to improve production efficiency, ensure product quality, reduce labor costs and risks, and simultaneously achieve energy saving. It is one of the important means for modern enterprises to pursue efficient production and sustainable development.

Benefits of Packaging Automation

-

Improved Production Speed

With the right automation packaging solution in place, it’s possible for companies to significantly improve production speed and product throughput. It’s not unusual for an automatic carton erector machine, for example, to box opening much more properly and several times faster than the average employee. Automatic packaging solutions can also multitask and fold multiple steps of the packaging process like sealing and labeling, into one single step. In additional, automated machines often require less maintenance and downtime for repairs, meaning that they can run for longer periods of time without interruption. As a result, automated packaging process can help to boost your business’s productivity and profitability.

-

Reduced Labor Costs

Right now, consumer demand continuing to rise, packaging companies are beginning to feel the effects of a competitive labor market. Workers have more options for employment, driving up wages and ultimately higher labor costs. Automation is one of the possible solutions to this problem. By automating as many packaging lines as possible, companies do not need to hire as many workers, but only when needed. Additionally, automated packaging is generally more reliable than manual packaging, which means you'll encounter fewer errors that can cause production delays.

-

Improvement In Quality Control

Automated packaging can help companies improve quality control for your business in a number of ways. For example: Automated machines can be set to apply consistent pressure when sealing products, ensuring that each package is sealed properly. Automated packaging systems include sensors that detect the correct size and shape of the product before it is packaged. This helps to reduce the risk of mistakes and product damaged. Automated packaging systems have precise, standardized settings that help improve product quality, cycles time and operations in general.

-

Improved Safety

Another key benefit of automated packaging processes is improved safety. There is always a risk of injury to workers performing tasks that involve repetitive movements to lifting, pulling and pushing heavy objects. Packaging automation reduces the necessity for this type of work, meaning that it also reduces the risk of worker injury. Not only you protect your team members, but you can also allow them to focus on less strenuous and more enjoyable workplace.

Key Solutions for Packaging Automation

-

Case Erectors and Case Sealers:

Our case erector and case sealers are perfect for handling uniform case sizes and different size cases. With rapid changeovers and precision forming, the packaging lines can handle everything from small personal items to bulkier products.

-

Pallet Stretch Wrapper:

From semi-auto to fully automatic stretch wrapping machine to our popular, we offer solutions that safeguard your palletized products, ensuring maximum load stability and protects during transit.

-

Shrink Wrapper:

Shrink wrapping is available for variety of product sizes and in both automatic and semi-automatic formats. When heat is applied to the film it shrinks tightly to whatever it is protective layer over them.

-

The Future of Automation

In an era of continuous technological advancement, the automated packaging industry is experiencing robust growth. With the manufacturing industry and consumer demands constantly expanding, the application of automated packaging technology is poised to become a trend in the future, and its significant implications for businesses and consumers.

-

Technological Innovation Driving Development

With the maturation and application of technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT), automated packaging systems will become more intelligent, flexible, and efficient. In the future, we will see the application of more innovative technologies such as vision recognition and robotic operations, enabling the automated packaging industry to better meet the evolving market demands.

-

Industry Upgrading Enhancing Competitiveness

The application of automated packaging technology will become one of the key means for the upgrading and transformation of the manufacturing industry. By introducing automated packaging systems, companies can enhance production efficiency, ensure product quality, reduce costs and risks, thereby improving competitiveness and expanding market share.

-

Product Personalization Demand

With the increasing demand for personalized and customized products, the flexibility and diversity of automated packaging systems will become a driving force for their development. In the future, we will see more automated packaging systems capable of meeting the needs of different product shapes, sizes, and packaging methods, thereby satisfying the diverse requirements of consumers.

-

Environmental Awareness

With the rise in environmental awareness, the energy-saving and eco-friendly features of automated packaging systems will become important advantages for their development. In the future, we will see more automated packaging systems capable of effectively reducing energy consumption and waste generation, thereby minimizing environmental impact and fulfilling corporate social responsibility.

Automated packaging can bring significant benefits to product manufacturers. By taking on repetitive and mundane tasks, automation can reduce the risk of ergonomic injuries and shift workers to higher-value tasks where they are needed. Automated packaging can also boost productivity and improve quality control measures, all of which translates to improved profitability in the long run.

You should choose automatic packaging machinery that suits your brand and products. This will help you to expand operations, while ensuring employee safety and profitability. Get in touch with Chuen An Pack today for more information.

-